New and Used Decanter Centrifuges

Alfawest supplies new, used or refurbished Solid Bowl Decanter Centrifuges from well-known manufacturers such as Alfa Laval, GEA Westfalia Separator, Sharples, and others. As a result, our customers can choose reliable equipment that matches both technical and budget requirements.

Thanks to a comprehensive overhaul process and delivery with a mechanical guarantee, our decanter centrifuges meet the highest quality standards. Consequently, customers receive dependable machines that perform comparably to new units.

Types of Decanter Centrifuges We Supply

Alfawest supplies almost all types of decanter centrifuges available on the market. Such as Alfa Laval Decanters and Centrifuges, Westfalia Decanters and Centrifuge, Flottweg Decanters and Centrifuges, Pieralisi Decanters and Centrifuges, Sharples Decanters and Centrifuges. In particular, our range includes:

- Two-phase separation decanters (solid bowl centrifuges) for liquid–solid separation

- Tri-canters (three-phase separation) for liquid–liquid–solid separation

In most cases, we deliver our decanter centrifuges with new PLC systems and modern control panels. Therefore, the machines integrate smoothly into existing manufacturing processes. At the same time, they deliver the performance and reliability expected from a new machine.

Customization, Testing, and Delivery

Moreover, we customize and thoroughly test all decanter centrifuges before delivery. As a result, we ensure consistent performance and operational reliability from the first start-up.

In addition, Alfawest offers some of the best delivery times and most competitive prices available in the market. For this reason, many customers rely on us for urgent and long-term projects alike.

Decanter Centrifuge Process and Applications

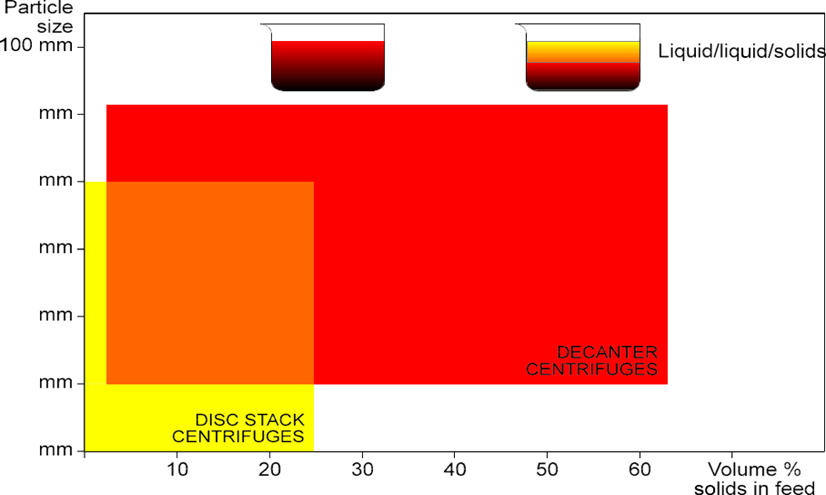

Decanter centrifuges are solid-material-oriented industrial centrifuges. Specifically, they process liquids and suspensions with high solid content, reaching up to 5–45% by volume, depending on the application.

Therefore, decanter centrifuges suit a wide range of industrial processes. For example, typical applications include:

- Clarification of liquids and suspensions

- Thickening of sludges

- Dehydration of sludges and suspensions

- Washing processes

- Wet classification of solid materials by grain size

- Extraction processes

- Separation of three-phase mixtures (two immiscible liquid phases and one solid phase)

Solid Bowl Decanter Centrifuges

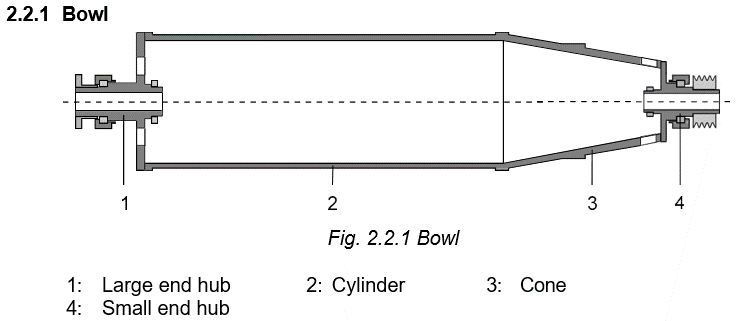

Solid Bowl Decanter Centrifuges consist of four main parts: a large end (front) hub, a cylindrical section, a conical section (extension), and a small end (rear) hub. The hubs support the main bearings, the conveyor bearings, the drive pulley, and the gearbox adapter.

In addition, the conical section includes one or two rows of solids discharge openings. In most cases, manufacturers line these openings with replaceable bushings or liners made from abrasion-resistant materials such as stellite or tungsten carbide. As a result, the bowl achieves higher wear resistance and longer service life.

Furthermore, the large end hub contains four or more liquid discharge openings. In some designs, solid bowl decanter centrifuges use a pressurized liquid discharge system. Specifically, this system operates through a paring disc (centripetal pump) positioned outside the large end hub.

Typically, an electric motor drives the bowl through V-belts and pulleys. Therefore, this configuration ensures stable operation and reliable torque transmission during continuous operation.

Conveyor

The conveyor rotates slowly relative to the bowl. As a result, it continuously transports sediment toward the solids discharge openings at the small end of the bowl. In this process, the axial advancement of the conveyor flight during one full rotation defines the pitch.

Generally, conveyors use a single-flight design. However, some applications require double-flight (two-start) conveyors to improve solids transport. Moreover, the flights may run perpendicular to the centerline or include a forward inclination (canted flights) to enhance conveying efficiency.